HOW SEE GLASSES ARE MADE

We’re “material snobs” and we're into meticulously crafted pieces. We’re not into mass market. We design and produce each piece in our collection exclusively for ourselves, and we only create a limited number of each style (usually only 1-2 per color of each style in each store). Why? We like individuality, and how can one be an individual if everyone on the street is wearing the same thing?

MATERIALS

MAZZUCCHELLI ACETATE

Our acetate is Mazzucchelli, the finest Italian cellulose acetate on earth, known for its strength, versatility, and most importantly its vibrant color. We like to add our own “mark”, so to speak, so we strive to create unexpected custom color combinations while keeping some timeless and classic eyewear in the collection.

MATERIALS

HINGES & HARDWARE

We care about beefy hinges and high quality crystals, and take great care to incorporate rigid standards for the factories we work with. We use 3, 5, and 7-barrel German hinges in our eyeglass frames, and if the mood strikes us, you might find a spring hinge or two on an ultra-lightweight frame. Our stainless steel and titanium hail from Italy and France, while our aluminum comes from Denmark.

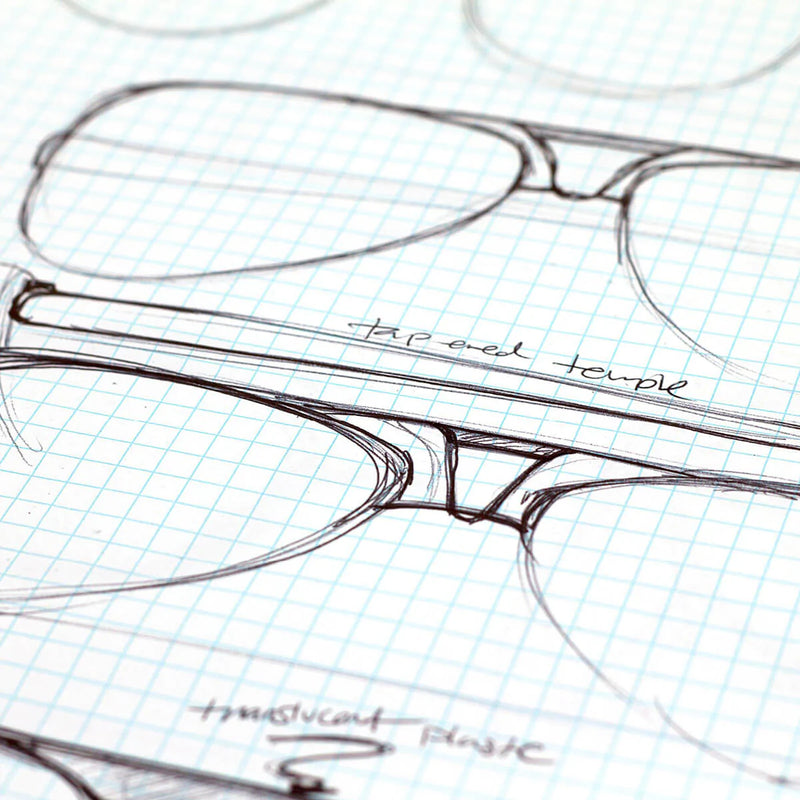

DESIGN

MULTIPLE PERSPECTIVES

Over the past 40 years, Randal and Richard Golden have developed relationships around the globe (including our hometown, Detroit) with the most forward thinking designers and artisans as well as some really innovative up-and-comers. They work hand-in-hand, collaborating on design and production in order to create a curated collection of the best of the best – exclusively for SEE.

CRAFTSMANSHIP

SHAPING UP

After the raw Mazzucchelli acetate is cut into frame fronts and temples, each piece is hand-sanded, removing debris and perfecting any imperfect edges in preparation for the next step - the tumbler!

CRAFTSMANSHIP

TUMBLE TUMBLE TUMBLE

Ever wonder why river rocks are so smooth? No? Well anyway, the same principle is applied to our acetate frames. Depending on the desired finish (matte, lustrous, ultra glossy), our frame fronts and temples go into the tumble drums and we let them tumble around in there for up to three days! Three whole days! Don’t worry about them, though. They love it in there. They’re having a blast.

CRAFTSMANSHIP

FINISHING TOUCHES

Now that we have our perfectly tumbled frames, with the perfect finish, exhausted from all that fun in the tumble drum, all the bits and pieces are assembled by hand, smoothed and hand-polished on a really fancy buffing wheel. The end product is a unique pair of lovingly designed, handcrafted eyeglasses - just for you.

RADICAL INDIVIDUALITY

CONCEPT TO COMPLETION

To produce a single SEE frame, from design conception to final product, takes the SEE product design and development team between four months and one year. The best part of this whole process is not that we get to flex our crafty design muscles, but that we are able to bring our enviable pieces to eyewear aficionados who are into radical individuality (and not into seeing every Tom, Dick and Harriet in their frame).